Category: Blog

Building a Safer Tomorrow at Rudraram, Hyderabad, Telangana

Aparna Enterprises celebrates a key milestone as the Rudraram facility in Hyderabad, Telangana, receives recognition for workplace security excellence. This acknowledgment reflects the company’s long-standing focus on creating safe, structured, and high-performing environments across all its manufacturing units.

Security is an outcome of consistent discipline, clear processes, and team alignment. The Rudraram team has demonstrated this through their dedicated efforts. From access control measures to employee training and infrastructure upgrades, every improvement has helped raise the overall standard.

This achievement also provides a clear reference point for future upgrades across other locations. The progress made at Rudraram offers both encouragement and a framework that can be replicated across additional facilities.

The focus now expands to wider safety initiatives. With this recognition in place, attention will grow toward ensuring that health and safety receive the same level of consistency and rigour.

Each achievement marks a new beginning. The journey toward better, safer, and stronger operations continues with purpose.

Upgrade Your Interiors with These Stylish Ideas

Your home is an extension of yourself and should reflect on your style, comfort and functionality. Whether you’re renovating or looking for inspiration, stylish upgrades in your living space completely transform the vibe of the house. In this blog, we are here to offer you fresh and functional ideas for interior design for home that seamlessly blend aesthetics with utility.

Elevate Your Cooking Space with Modular Kitchen Designs

The kitchen, being the heart of the home, is the starting point for everything. It’s more than a place to cook; it’s where conversations unfold, memories are made, and morning rituals are underway. Elevating your kitchen significantly lifts the overall feel of your interiors and improves the functionality as well!

Modular kitchen designs are thoughtfully curated and are the leading trend among modern homeowners. The differentiation point is their systematic approach to kitchen planning, wherein each unit is a module, designed to fit seamlessly with others. This creates a cohesive, organised layout offering the perfect balance of aesthetics and functionality ,featuring elegant finishes, ergonomic designs and smart storage solutions.

In Hyderabad, modern lifestyles present specific challenges that demand kitchens be both practical and elegant.We offer modular kitchen designs in Hyderabad that are adaptable to any space, be it a compact city apartment or a spacious villa , but also offer design features that ease into the busy lifestyle with a wide array of materials, colours, and finishes.

Key features to consider include modern kitchen cabinets equipped with soft-close hinges, pull-out trays, and vertical storage for better space management. These cabinets are now available in high-gloss laminates, acrylic, or glass finishes, each adding a distinct style to your cooking area. Open shelving is another trending kitchen cabinet design that enhances visual openness while allowing easy access to essentials.

Color schemes can significantly influence the kitchen’s vibe. Dual-tone schemes such as white and wood, navy and brass, or pastel blues with matte black accents are currently trending. Accent lighting under cabinets, stylish backsplashes, and integrated appliances complete the picture of a sleek, functional modular kitchen that’s every modern chef’s dream.

Add Style & Function with Sliding Wardrobe Designs

Wardrobes are essential in every home, not just for storage but also for their impact on interior aesthetics. The traditional bulky cupboard has made way for modern, sleek, and efficient sliding wardrobe designs, a smart innovation that’s both space-saving and visually appealing.

The key advantage of sliding wardrobes is their ability to seamlessly fit into tight spaces without restricting movement. Unlike hinged wardrobes, sliding doors glide smoothly along tracks, a perfect mechanism ideal for rooms with limited space. This makes them especially popular in urban homes and apartments where maximizing space is critical.

When aiming for a contemporary look, incorporating a wardrobe with sliding doors and mirrors is a game-changer. The mirrored surface serves a dual function: it reflects natural and artificial light to make the room feel brighter and more expansive, and it eliminates the need for a separate dressing mirror, further conserving space.

In terms of visual appeal, modern sliding wardrobes now come in a wide variety of materials and finishes that can add another layer of depth to them. Matte-finishes offer a subtle, modern touch while high-gloss finishes are a bold statement that exudes luxury. Wood grain textures add warmth and a rustic charm, perfect for cozy, traditional-style interiors.

Customization of the sliding wardrobe is another standout benefit. You can choose from multiple internal configurations from drawer units, hanging spaces, shoe racks, and even fold-out ironing boards, to suit your lifestyle. Add LED strip lighting inside the wardrobe for added visibility and a high-end feel.

For those looking to harmonize functionality and visual appeal, sliding wardrobe designs deliver the perfect blend. Whether it’s a master bedroom, guest room, or walk-in closet, they elevate your storage game while amplifying your room’s style quotient.

Choose Floor Tiles That Reflect Your Style

Flooring often defines the character of a room. Whether you’re revamping your living room, kitchen, or bathroom, there’s a world of floor tiles designs to explore. From rustic wood-look tiles to glossy ceramic or anti-skid vitrified options, there’s something for every theme.

Let Natural Light In with Aluminium Windows and Doors

Far more than structural necessities, doors and windows shape the ambiance and style of every room.It should not be overlooked as they play a crucial role in determining the overall

interior design for home. Upgrading to aluminium windows and doors is an investment for the long run as it provides the dual benefit of improved energy efficiency and ventilation.

Their sleek frames, durability, and weather resistance make them a preferred choice among architects and homeowners alike.

Experience Seamless Living with uPVC Windows and Doors

Another top recommendation in modern interiors is switching to uPVC windows and doors.

Known for being lead-free uPVC windows and doors are known for the best security, thermal insulation and soundproofing capabilities. Considering if you reside in hustling cities the noise can prove to be a nuisance and uPVC windows and doors can make your home quieter, cooler and more secure.

Choose from casement styles, tilt-and-turn windows, or French doors to complement your interior theme.

Style Meets Comfort: Accessories & Accents

Small details matter. Once the big-ticket items are sorted, consider accessorizing with soft furnishings like textured cushions, area rugs, ambient lighting, and indoor plants to complete the look.

Incorporate open shelving, floating vanities, and mixed materials to add depth and personality to your space. Thoughtfully chosen art pieces and layered lighting can make any room feel cozier and more lived-in.

Conclusion: Make Every Corner Count

Upgrading your home doesn’t always require a massive renovation. With the right choices from modular kitchen designs and floor tiles designs to UPVC windows and doors you can enhance every nook and cranny. These stylish ideas not only reflect the latest trends in interior design for home but also cater to comfort, efficiency, and lasting appeal.

Ready to transform your space? Let design meet durability with Aparna Enterprises’ trusted brands and bring your interior vision to life.

Top 10 Modern Vitrified Tiles Designs Trending in 2025

In 2025, vitrified tiles design is evolving fast, blending innovation with timeless aesthetics. Whether you’re building a dream home or redesigning commercial spaces, these modern tile styles help create bold, clean, and functional surfaces.

Explore the top vitrified tile design ideas that are setting the tone for interiors this year.

1. Large-Format Vitrified Tiles

With fewer grout lines, large-format vitrified tiles deliver a seamless, spacious effect. They enhance the sense of scale in any room and reduce visual clutter.

Common spaces: Living rooms, hotel lobbies, commercial floors.

2. Marble-Look Vitrified Tiles

Vitrified tiles designed to resemble natural marble offer a luxurious finish with easier maintenance. Their veining patterns and polished look make them a favourite for premium interiors.

Used in: Bathrooms, dining areas, corridors.

3. Wood-Finish Vitrified Tiles

These tiles offer the warmth and texture of wood but outperform timber in terms of moisture resistance and durability.

Popular applications: Bedrooms, lounges, outdoor sit-outs.

4. Textured Surface Vitrified Tiles

Textured vitrified tiles bring dimension and depth to plain walls and floors. Stone textures, geometric patterns, and matte finishes create a designer appeal.

Best for: Feature walls, reception areas, staircases.

5. Glossy Polished Vitrified Tiles

High-gloss vitrified surfaces reflect light beautifully and make rooms feel bright and open. Available in neutral and rich tones, they are often used for a luxurious finish.

Common areas: Drawing rooms, offices, showrooms.

6. Matte-Finish Vitrified Tiles

Sleek and modern, matte vitrified tiles are trending due to their subtle elegance and slip-resistant surface.

Ideal for: Bathrooms, kitchens, entryways.

7. Digital Printed Vitrified Tiles

Modern printing techniques now bring unique designs to vitrified tiles. From artistic florals to stone-like textures, these offer creative freedom.

Great for: Wall panels, hotel rooms, boutique stores.

8. Stone-Effect Vitrified Tiles

Inspired by granite, slate, or limestone, stone-look vitrified tiles replicate natural ruggedness while maintaining uniform quality and strength.

Often used in: Terrace areas, outdoor patios, rustic kitchens.

9. Monochrome Vitrified Tiles

Black, white, and grey tiles are being used in bold layouts—checkerboard, diagonal stripes, or herringbone—for clean and modern aesthetics.

Best for: Hallways, kitchens, cafés.

10. Eco-Friendly Vitrified Tiles

New vitrified tiles are being made using recycled content and sustainable manufacturing processes, helping reduce carbon footprints while offering modern appeal.

Usage: Residential buildings, public institutions, sustainable homes.

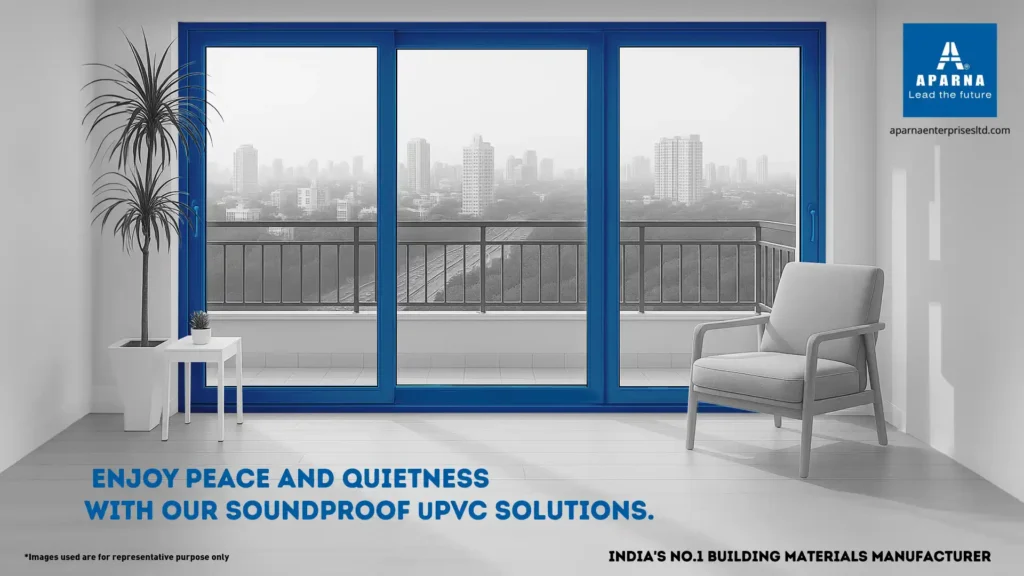

Enjoy Peace and Quietness with Our Soundproof uPVC Solutions

In today’s modern lifestyle, peace and quiet have become luxuries as we are surrounded by distractions. Whether you’re working from home, relaxing with your family, or simply want some personal space, the environment you create plays a major role in your home. That’s why choosing the best soundproof windows for home is not only about the visual appeal, it’s the quality of lifestyle. At Aparna Enterprises Limited, our uPVC solutions are engineered to keep the noise out and helps to experience the calm indoors.

Why Soundproofing Matters More Than Ever

Urban living has its upsides when it comes to opportunities, but it also has major distractions – traffic, construction, loud neighbours, and more. The chaotic environment and the noises can be overwhelming when the circumstance calls for peace. It is important to have the right soundproof solution that helps to transform your space into a serene sanctuary. Our range of uPVC window designs and sliding doors and windows are manufactured to create acoustic comfort while complementing the aesthetics of your home.

The Science Behind Our Soundproof uPVC Windows and Doors

Our uPVC doors and windows are made with multi-chambered profiles, double or triple glazing, and silicone sealing technology to reduce noise pollution. These features are designed to provide the dual-benefit of sound insulation and energy efficiency, which is discussed further.

Whether you’re choosing casement doors and windows or a sliding door uPVC setup, every design element is optimised for performance and silence.

Noise Pollution: A Rising Concern

According to the World Health Organization (WHO), sustained exposure to noise levels exceeding 55 decibels (dB) can significantly affect health, contributing to increased sleep disorders, reduced cognitive function, irregular hearing, increased stress and even cardiovascular complications. When taking into account densely populated areas across India, ambient noise levels regularly go beyond 70 dB due to the floating population, restless traffic, construction activity and crude public spaces. The following figures highlight not just an environmental concern but a growing public health issue in places across India.

- A 2023 study found that 75% of residential areas in Mumbai experience daytime noise levels above 70 dB(A), significantly higher than the permissible 55 dB(A) set by India’s Central Pollution Control Board.

- In Chennai, ambient noise frequently exceeds 65 dB at night in many central zones (like T‑Nagar), well above the TNPCB’s 55 dB limit for commercial areas.

- According to CPCB data via the National Ambient Noise Monitoring Network, road traffic noise regularly surpasses 70 dB(A) in most major Indian cities, including Delhi, Mumbai, Kolkata, and Bangalore.

With these stats in mind, it is imperative that noise management indoors is a necessity. That’s where Aparna Enterprises Limited steps in. We made a firm commitment to design and wellbeing, offering cutting edge soundproofing solutions through our range of high-performing uPVC windows and doors. Engineered with multi-chambered profiles, high-grade sealing systems, and double-glazing options, these products are specifically designed to reduce external noise and create a quieter, healthier home environment.

By integrating acoustic insulation with aesthetic finesse, Aparna Enterprises enables homeowners to reclaim peace in their spaces—ensuring that comfort and calm are not compromised by the chaos outside. In an age of rising noise pollution, AEL doesn’t just build interiors; it builds sanctuaries.

Explore Our uPVC Range: Style Meets Silence

1. uPVC Window Design

Our diverse range of uPVC window designs offers everything from traditional aesthetics to contemporary lines. Options include tilt-and-turn, sliding, casement, and fixed window configurations—each crafted with high acoustic insulation in mind.

If you’re searching “windows uPVC price,” you’ll find our offerings competitive and value-packed. Plus, the added benefit of noise reduction makes them a smart long-term investment.

2. Sliding Doors and Windows

Perfect for balconies, patios, and large openings, our sliding doors and windows combine smooth operation with maximum coverage and minimal noise intrusion.

With airtight locking and double-glazed panels, our sliding design for home solutions are ideal for families, professionals, and anyone seeking functional elegance.

3. Casement Doors and Windows

For those who prefer classic, inward-opening formats, our casement doors and windows offer both versatility and superior noise control. Fitted with premium gaskets and robust hinges, these doors are engineered for a tight seal and exceptional sound reduction.

4. Fold and Sliding Doors

Need more flexibility? Our fold and sliding doors provide wide, seamless openings while maintaining acoustic integrity. These are great for merging indoor and outdoor spaces without compromising on privacy.

Benefits Beyond Soundproofing

Our uPVC windows and doors across India offer more than noise control:

- Enhanced energy efficiency

- Low maintenance and weather resistance

- Long-lasting color and shape stability

- Increased security with multi-point locking systems

Trusted by Thousands: Why Homeowners Choose AEL

- Quality That Speaks for Itself: Our reputation as one of the top uPVC doors and windows suppliers comes from our commitment to quality and innovation.

- Tailored to Your Home: Every product can be customised to suit your space, noise level, and design preferences.

- End-to-End Service: From consultation to installation, we guide you through the process.

Whether you’re looking for uPVC windows and doors in Hyderabad or beyond, AEL is your trusted partner for performance-driven living solutions.

Make Silence a Standard

Upgrading your home comes with a lot of benefits, but the most meaningful moments are not often seen but felt. In this case, what you don’t hear. Unnecessary noise has become a part of everyday life, yet it does not have to have a hold on your home. With Aparna Enterprises Limited’s industry leading soundproof uPVC solutions, your investment is in the right place not for windows and doors but for a peace of mind.

Whether you’re looking to reduce urban noise, improve thermal efficiency, or simply create a serene ambiance, Aparna Enterprises delivers an unmatched blend of innovation, quality, and comfort. With advanced features and tailored configurations, our soundproofing solutions cater to every lifestyle and architectural needs.

Explore our latest range of uPVC window designs, fold and sliding doors, and soundproof systems today,because a quieter home is a better home.

Why Unispace is Your Go-To for Elegant and Efficient Interiors

The modern urban landscape offers a plethora of home interior design ideas that demand a blend of style, utility, and enduring quality. Unispace by Aparna Enterprises Limited offers exactly that, transforming spaces into urbane expressions of taste and functionality. Whether you’re designing your dream kitchen, upgrading your wardrobes, or installing new windows and doors, Unispace offers comprehensive solutions tailored to modern living.

Unispace: The Smart Choice for Contemporary Living

At Unispace, design meets durability. Every element curated from Unispace is crafted with the lifestyle of contemporary living. From modular kitchen designs to wardrobe with sliding doors and mirrors, it is crafted by keeping visual appeal and everyday performance. This actually makes Unispace a lifestyle enabler.

We believe that true elegance can be showcased to its truest beauty when intentionally designed, utilising smart usage and premium finishes. Our solutions reflect a deep understanding of how modern families live, work, and relax at home.

Kitchen Cabinet Designs that Blend Form and Function

One of the most delicate and sought-after aspects of any home is the kitchen. At Unispace, we specialise in kitchen cabinet designs that blend sleek aesthetics with intelligent storage compartments. With options ranging from modern kitchen cabinets to customisable ergonomic finishes, Unispace caters to every taste.

Our modular kitchen designs echo taste and are not only stylish but also space-saving. Crafted using premium materials, they endure the daily wear while enhancing your cooking space. Whether you prefer minimalistic lines or classic wood finishes, Unispace creates kitchens that become the heart of your home.

With Unispace, your kitchen doesn’t just serve its purpose – it becomes a statement. Designed to reflect your personality and cooking style, our kitchen solutions are crafted for the connoisseur in you.

Stylish Sliding Wardrobe Designs for Urban Homes

Gone are the days of bulky almirahs. Today, sliding wardrobe designs are the go-to for urban households. Unispace offers sleek, aesthetically pleasing and functional wardrobes that maximise room space and provide elegant storage solutions.

Designed with purpose and built for harmony, our wardrobes elevate every space they’re part of. Thoughtful interiors, adjustable shelving, and innovative components add to the aesthetics along with functionality. With integrated mirrors, soft-close features, and customisable layouts, our wardrobe with sliding doors and mirrors collection is ideal for master bedrooms and any space where your fashion sense can thrive.

Incorporating high-quality materials and contemporary finishes, Unispace wardrobes stand the test of time. They’re not just furniture; they’re smart storage systems that elevate your lifestyle.

Flooring that Speaks Style: Floor Tile Designs to Watch

The foundation of every great design is the flooring. Our curated floor tile designs include modern patterns, earthy tones and luxurious textures suitable for every space from living rooms to bathrooms. Explore vitrified tiles in finishes ranging from matte to high gloss—designed to deliver both resilience and refined aesthetics.

Each tile is chosen for its durability, ease of maintenance, and aesthetic value, giving you floors that are as stunning as they are long-lasting.

What sets Unispace apart is our commitment to offering a wide array of choices – from vitrified to ceramic to digitally printed tiles – that meet the diverse needs of Indian homes. Whether you’re going for minimal, eclectic, or luxurious, our floor tiles fit effortlessly into your design vision.

Tailored Solutions for Every Room in Your Home

At Unispace, we don’t just curate and design kitchens and wardrobes, we aim to transform entire homes. Our expertise extends to overarching home interior design ideas that intentionally consider every nook and corner for your living space. Whether it’s a serene study room, a multifunctional family area, we approach every space with the same level of precision, creativity and purpose.

What sets Unispace apart is our commitment to creating holistic interior systems — designs that are not only beautiful in isolation but also work together in harmony. From coordinating materials and finishes across kitchens, wardrobes, tiles, and even door-window systems, we ensure every element flows seamlessly into the next. The result is a cohesive, well-curated home environment that reflects both your style and your way of life.

We also ensure our products work together harmoniously, coordinating finishes across kitchens, tiles, and door-window systems for a seamless interior aesthetic.

Why Choose Unispace for Your Interiors?

1. Comprehensive Range: From flooring to furniture, Unispace covers all core interior elements.

2. Custom Solutions: Tailored designs that adapt to your lifestyle and preferences.

3. Premium Quality: We collaborate with top material providers to deliver long-lasting beauty.

4. Pan-India Reach: Available across metro and tier-2 cities, including Hyderabad, Bangalore, and Vijayawada

5. Innovative Design: Our product development is driven by emerging trends and customer feedback.

Elevate Your Home with Unispace

At Unispace, we understand the human thought of home design being more than just finishes and fittings, it’s a reflection of your personality, lifestyle and aspirations. No matter if it’s a revamp of your home or a fresh space from the ground up, our solutions are adaptable to your preferences. From floor tiles that speak sophistication to modular wardrobes that redefine functionality, every detail is thoughtfully curated to bring an elevated experience for your everyday life.

The trends come and go, but timeless interiors stay. We are forward-thinking, blending contemporary aesthetics with function and elegance with ease. Our three pillars—quality, design precision, and personalized service—bring your vision to life so that every space exudes beauty.

To us, a well-designed home isn’t just about aesthetics, it’s about how seamlessly it supports your daily rhythm.

Step into a world where style meets substance. Step into Unispace.

Visit our showroom or connect with our design experts to start your journey toward smarter, more beautiful living today.

Why Aluminium Window Frames Work for Indian Homes

Aluminium window frames have become a preferred choice for homeowners in India due to their unmatched durability, modern appearance, and low maintenance needs. Whether you’re renovating an apartment in Delhi or building a villa in Bangalore, aluminium frames offer strength and style suited for Indian weather and lifestyle demands.

Benefits of Aluminium Window Frames

Weather-Resistant and Long-Lasting

Aluminium doesn’t rust, crack, or warp in extreme conditions. From coastal humidity to dry heat, aluminium window frames stand firm.

Modern Design with Slim Profiles

Minimalistic frame designs allow maximum natural light and uninterrupted views. They’re compatible with both modern and traditional architecture.

Minimal Upkeep Required

Unlike wooden frames that require regular polishing or repainting, aluminium needs only occasional cleaning with water and mild soap.

Environmentally Sustainable

Aluminium is 100% recyclable and has a smaller environmental footprint compared to uPVC or wood, making it an eco-conscious material.

Popular Types of Aluminium Window Frames in India

Sliding Frames

Ideal for small spaces like balconies or kitchens. These offer ease of use without swinging in or out.

Casement Frames

Hinged on the sides, they open outwards or inwards. These are highly energy-efficient with better sealing capabilities.

Tilt and Turn Frames

Provide flexible opening options—tilt for ventilation, turn for full access. These are perfect for high-rise buildings or modern homes.

Fixed Frames

Used where ventilation is not required but sunlight is essential. These are often paired with other types for a balanced layout.

How to Choose the Right Aluminium Window Frames

Check Frame Thickness and Grade

Choose a frame with at least 1.2 mm thickness for durability. Anodized or powder-coated finishes enhance resistance to corrosion and wear.

Select the Right Glass

Double-glazed or laminated glass improves insulation and noise reduction. In high-traffic areas, acoustic glass is a smart investment.

Inspect Hardware and Locking Mechanisms

Go for high-quality locks and hinges. Multi-point locking systems add an extra layer of security.

Evaluate Thermal and Acoustic Insulation

Aluminium frames paired with thermal break technology reduce heat gain and offer better energy efficiency in warm regions.

Aluminium Window Design Trends in India

- Matte Finishes in Black, Grey, or Champagne: Popular for urban homes seeking a clean and classy aesthetic.

- Wood Grain Powder Coating: Offers the traditional look of wood with the benefits of aluminium.

- Slimline Profiles: Allows larger glass areas, ideal for panoramic views and better lighting.

- Smart Windows: Integration with home automation systems for remote control and sensors.

Maintenance Tips for Aluminium Frames

- Clean every few months using a mild detergent and soft cloth.

- Inspect drainage holes and silicone joints after monsoon.

- Avoid abrasive materials to maintain the surface finish.

- Apply a lubricant to sliding channels once a year for smoother movement.

Why Aparna Enterprises Ltd. Stands Out

Aparna Enterprises Ltd. offers custom-engineered aluminium window frames that meet international standards, backed by superior materials and expert craftsmanship. Our range includes energy-efficient, soundproof, and designer frame systems tailored for Indian households. Every product is tested for performance, aesthetics, and longevity—perfect for both urban and rural residential needs.

How Aluminium Window Designs Create Aesthetic and Functional Living Spaces

In the world of modern architecture and interior design, windows are no longer just practical necessities for light and air. They have evolved into crucial architectural elements that define how a space feels and functions. This transformation has been made possible by the expertise and innovation of the aluminium window designs.

Aluminium windows are now a benchmark in contemporary design, providing not just structural support but also helping shape minimalist, elegant, and energy-efficient environments. The rise of aluminium as a material of choice for modern buildings is largely due to the way designs leverage its inherent properties to create balance between beauty and performance.

What Sets Aluminium Apart in Window Design

Aluminium is valued in the building industry for a number of reasons. It is lightweight, highly durable, corrosion-resistant, and has a sleek appearance that naturally blends itself to modern aesthetics. These attributes empower any aluminium window designs to build thinner frames with larger glass spans, creating an uninterrupted connection between indoor and outdoor spaces.

Unlike wood or uPVC, aluminium doesn’t warp, expand, or degrade quickly—making it a reliable long-term choice, especially in regions with extreme weather. From urban apartments to commercial facades and luxury homes, aluminium remains a top-tier material due to its blend of performance and visual appeal.

The Design Philosophy Behind Aluminium Windows

A successful aluminium window designs does not simply think in terms of frames and glass. Their role is to ensure the window enhances spatial quality, allows more natural light, and integrates seamlessly into the architecture of the space.

Design elements commonly prioritized include:

- Ultra-slim frames that give a clean, minimalist finish

- Neutral or bold powder-coated finishes to match different decor styles

- Hidden or integrated hardware for a seamless appearance

- Custom glazing options for light control and privacy

These elements, combined with technical detailing, elevate aluminium windows from functional objects to curated design features.

Customization Is the Key to Personalized Living Spaces

One of the major reasons homeowners and architects prefer working with an aluminium window designs is the level of customization available. Unlike traditional window systems, aluminium windows can be designed to fit virtually any dimension or specification.

Designs offer flexibility in:

- Color finishes: From matte black to woodgrain textures

- Opening types: Casement, sliding, tilt-and-turn, pivot, or fixed

- Glazing: Single, double, or triple glazing, tinted or frosted

- Hardware: Choice of premium handles, locks, and hinges in multiple finishes

Customization ensures the final product not only functions perfectly but also blends with the aesthetics of each project.

Technological Innovation Drives Performance

Today’s aluminium windows are engineered for more than just beauty. Aluminium window designs incorporate cutting-edge materials and fabrication techniques to improve thermal efficiency, safety, and acoustic control.

Some of the latest advancements include:

- Thermally broken frames to prevent heat transfer and reduce energy consumption

- Multiple seal systems to block noise and dust

- Laminated or toughened safety glass to meet security requirements

- Micro-textured surfaces that resist scratches and fading

These innovations make aluminium windows a smart choice for both eco-conscious and performance-driven consumers.

Tested for Durability and Real-World Resilience

Quality assurance is a major part of what distinguishes professional aluminium window design. Reputed systems are tested for:

- Wind pressure resistance

- Water penetration and drainage

- Air leakage performance

- Impact strength and long-term structural stability

An experienced aluminium window designes ensures these standards are met before finalizing a product. This means homeowners can trust that their windows won’t just look beautiful when new, but will continue to perform reliably for years—even in coastal regions, high-rise buildings, or high-rainfall areas.

Sustainability and the Aluminium Advantage

As sustainability becomes a driving force in construction, aluminium stands out as one of the most environmentally responsible materials in the industry. Aluminium is 100% recyclable without degradation, and the recycling process uses only 5% of the energy required to produce new aluminium.

For aluminium window designs, this is a major advantage. By choosing aluminium systems, they support green building certifications (like IGBC and LEED), reduce overall project carbon footprints, and contribute to long-term environmental goals.

We use recycled aluminium in our systems, ensuring sustainability without compromising on quality or aesthetics.

Quality, Warranty, and Assurance Matter

The best aluminium window systems are supported by strong warranties, ensuring buyers get long-lasting value.

- 10 years warranty on powder-coated or anodized finishes

- Up to 5 years warranty on hardware components

- Installation warranties when handled by certified fabricators

A qualified aluminium window designs ensures that products come with proper documentation, testing certificates, and maintenance guidelines. This level of professional oversight protects the client’s investment and ensures consistency in quality.

5 Smart Space-Saving Ideas for Homes by Unispace

Clutter makes your home feel smaller because of the humongous amount of stuff not organised properly. Decluttering in the most truthful sense doesn’t mean throwing things out, it’s rethinking how you can accommodate using existing space.

At Unispace, our ethos is that smart design is the best and quite underrated way to regain control over your living space. Whether you live in a cosy apartment or a stylish duplex, our space-efficient solutions help you get more from every square foot.

With a focus on space-saving ideas for homes, modular kitchen designs, and custom wardrobes, we are discussing how Unispace helps you eliminate clutter without sacrificing style.

1. A Kitchen That Works Smarter, Not Harder

Beginning with the heart of the home, the kitchen, when designed poorly, becomes a hindrance to the overall look and feel of the home. They can also become the biggest clutter zones in a house, but a neatly designed modular kitchen can completely change the outlook and perspective of how you can use that space.

Unispace offers the best modular kitchen design options with optimised layouts, pull-out systems, built-in storage, and seamless finishes. These kitchens are built for high functionality, letting you store more in less space.

Our experts will walk you through real-time layouts, materials selection and aid you in bringing your design vision to life so that you can have a clear picture of what you’re investing in.

You can be rest assured that Unispace offers the best modular kitchen design that not only brings your design vision to life but also smoothly integrates with the overall feel of the home.

2. Slide Into Efficiency: Smarter Wardrobe Design

Sliding into the second most important thing in the house, the wardrobes. It’s time for a layout upgrade if your wardrobe doors open wide into walkways or squeeze past your bed. Uniispace’s sliding wardrobe designs let you reclaim space without compromising on storage capacity or style.

Sliding doors eliminate the need for door clearance while giving your wardrobe a clean, modern look. Plus, with space-saving ideas for homes like soft-close systems, mirrored panels, and internal drawers, organising becomes intuitive and elegant.

For those who have an acquired taste for lux, explore our luxury wardrobe doors wherein design meets decadence. Unispace helps in your hunt for the supreme finish, whether it’s matte finishes or high-gloss lacquered panels. Choose materials that align with your aesthetic and lifestyle.

3. A Touch of Transparency: Glass Wardrobes That Inspire

Now for fashion-forward individuals or people who love an open concept look, our range of clear glass wardrobe doors creates a ravishing look that is modern, sleek and functional.

The glance at your wardrobe’s contents helps reduce clutter, impulse shopping, and daily wear confusion. Combine it with soft lighting to lift the aesthetic up or make it into colour-coded sections, and you have a walk-in closet experience without needing a separate room

For a more subtle option, wardrobe doors with glass panels provide visibility with a touch of mystery—perfect for balancing transparency and tidiness.

4. Modular Storage, Customised to You

Not every family member uses the space the same way, and Unispace understands that. From kids’ rooms with growing storage needs to concise apartments where space can feel like luxury, we offer modular cabinets design to suit and adapt to your daily life.

Built-in spice racks, dual-height counters, hydraulic lifts, drawer organisers—each solution we offer is designed to create breathing room in your kitchen while making it easier to access the things you use most.

Your space should work twice as hard when living in busy urban environments like Hyderabad. We deliver space-saving ideas for homes that do exactly that, built for urban homes and modern living.

5. The Hidden Power of Local Expertise

When you search for a modular kitchen , what you really want is someone who understands your space, your lifestyle, and your pace. Unispace brings together expert designers and skilled installers who know local trends and challenges, especially in fast-growing metro cities.

Why Choose Unispace?

At Unispace, we don’t just design interiors—we redefine how homes function. Our approach goes beyond aesthetics. We merge ergonomics, intelligent design, and material durability to create solutions that evolve with your life.

Whether you’re a minimalist looking for clean lines or a busy household in need of smart storage, Unispace brings your vision to life through:

- Tailor-made modular kitchens built for real-world use

- Wardrobe systems that fit perfectly, even in awkward corners

- End-to-end service: From consultation to installation

- Expert teams in Hyderabad and across metro cities

With a commitment to quality and innovation, we’ve become one of the top choices for homeowners seeking space-saving ideas for homes that feel fresh, functional, and future-ready.

Declutter & Redesign Your Perspective

At the end of the day, clutter isn’t about how much stuff you own—it’s about how well your space supports your lifestyle. With Unispace’s space-saving ideas for homes, you don’t just get more room—you get more ease, more organisation, and more time back in your day.

From modular kitchen designs to modern wardrobe doors, our solutions are designed to eliminate visual noise and replace it with clarity.

Looking to reclaim your home from the clutter? Start your design journey with Unispace today.

Discover Elegant Home Improvement Solutions by Unispace.

Your home is a place of belonging, a personal sanctuary that is a reflection of your style and the centre piece to countless memories. When it’s time to refresh or reimagine your living spaces, the desire for opulence, functionality and quality is at the top of the primary checklist. At Aparna Unispace, we empathise with this aspiration, providing a sensational range of the best home improvement ideas through our sophisticated modular solutions. From stunning modular kitchen designs to space-saving sliding wardrobe designs and exquisite floor tiles designs,

Unispace encourages you to create an oasis that embodies the vision of refined and revitalising living.

Crafting Culinary Dreams with Elegant Kitchens

The heart of the home deserves special attention, and Unispace offers modular kitchen designs that transform your culinary space into a haven of efficiency and style. Whether you envision sleek and modern kitchen cabinets or a more classic and warm ambience, our diverse range of finishes, layouts, and innovative storage solutions seamlessly blends aesthetics with practicality. Discover the perfect kitchen cabinet designs that suit your taste and lifestyle, creating a culinary paradise that reflects beauty, and ultimately, you will be happy to use. Explore our selection of premium materials, enabling you to customise every detail—from countertops to cabinet handles—to match your unique vision. At Unispace, we believe your kitchen should not only serve your culinary needs but also inspire creativity and comfort. Innovative storage solutions, such as pull-out pantries, soft-close drawers, and clever corner units, maximise space utilisation while maintaining a clutter-free and elegant aesthetic. Let us help you craft a space where functionality meets elegance and every meal becomes a moment to cherish.

Optimising Space with Stylish Wardrobes

In urban living, maximising space without compromising on style is crucial. Unispace offers a stunning collection of sliding wardrobe designs that provide ample storage while adding a touch of contemporary elegance to your bedrooms. Our sliding wardrobe with mirrors not only enhances functionality but also creates an illusion of spaciousness and reflects light, brightening your interiors. Explore our diverse range of finishes and configurations to find the perfect wardrobe with sliding doors and mirrors that meet your storage needs and elevate your bedroom décor.

Laying the Foundation for Elegance with Exquisite Flooring

The choice of flooring entirely depends on the overall look and feel of your home. Unispace offers a specialised selection of floor tiles designs that range from the classics to contemporary trends and a blend of both. Whether your preference lies with warmth or moody tones, natural textures or the sleekness of modern materials, our premium quality floor tiles designs not only match your aesthetic but also fit your lifestyle needs. Elevate your home with flooring that merges functionality with refined design because every step should feel just right.

Enhancing Light and Airflow with Premium Windows and Doors

One of the crucial elements of interiors is the windows and doors, wherein they establish the comfort of the environment. At Aparna Unispace, we recognise the importance of high-quality windows and doors and the interplay of natural light and ventilation. We recommend considering the sophistication and robustness of aluminium windows and doors, known for maximising glass area, allowing an abundance of natural light and offering a sleek, modern aesthetic. The inherent strength also ensures durability and security! Alternatively, uPVC windows and doors provide exceptional energy efficiency benefits through their superior insulation properties. With uPVC windows and doors, they help maintain a comfortable indoor temperature, reduce outside noise and are a significant advantage for busy homeowners who are looking for peace and quiet.

The right windows and doors are not just functional openings but vital elements in creating a bright, airy, secure, and elegant home.

Completing the Look with Thoughtful Details

The concept of home improvement transcends beyond the selection of major installations like kitchens, wardrobes and flooring. The true essence of a refined living often lies in the thoughtful pieces and small details that matter the most to you. Consider the power of creativity that reflects your taste and the transformative power of home improvement from a holistic perspective.

Elegant handles, knobs, and hinges can elevate the overall aesthetic, adding a touch of sophistication. Carefully chosen lighting fixtures play a crucial role in setting the mood and highlighting key features within your home. From ambient ceiling lights to focused task lighting and decorative wall sconces, the right illumination can dramatically enhance the elegance and functionality of each space. Finally, the selection of carefully curated accessories, such as decorative mirrors, artwork, textiles, and plants, adds personality, warmth, and a sense of completion to your home.

Let’s Create Your Dream Space

Creating an elegant home is a journey of thoughtful choices and attention to detail. With Aparna Unispace, you gain access to a world of sophisticated best home improvement ideas, from beautifully designed modular kitchen designs and space-saving sliding wardrobe designs to exquisite floor tiles designs. While considering the importance of quality aluminium windows and doors and uPVC windows and doors, focus on creating a cohesive and harmonious living environment that reflects your personal style and enhances your everyday life. Discover the elegance and functionality that Unispace can bring to your home improvement aspirations.

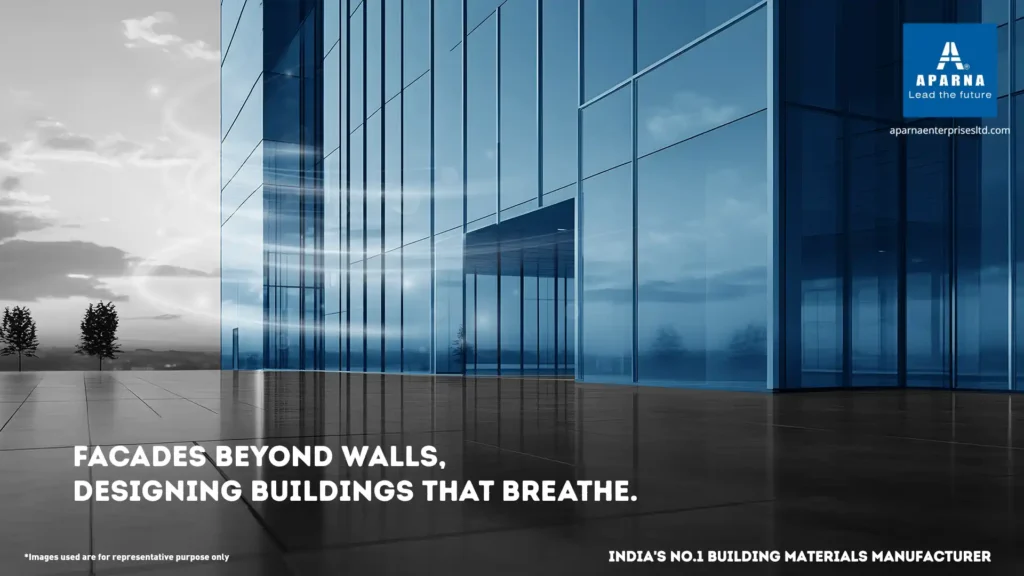

Facades Beyond Walls. Designing Buildings That Breathe.

The typical stereotype of viewing a building facade as a protective shield against the elements is transforming and shifting to a whole new paradigm. Presently, visionary architects and pioneering materials manufacturers such as Aparna Enterprises Ltd., are refashioning building facades design to build marvellous structures that engage and adapt with their surroundings. These “breathing” buildings lay the foundation of natural light and airflow which helps establish a coherent relationship between indoor and outdoor spaces. This in turn promotes healthier and more sustainable urban environments.

The factor that is spearheading this transformation is the intelligent use of materials like glass, expertly engineered into sophisticated systems. From expansive glass facades that flood interiors with daylight to intricate suspended glass assemblies that redefine spatial flow, glass is no longer just a window – it’s a dynamic element in creating architecture that truly lives.

The Transparency and Lightness of Glass Facades

For a good reason, glass facades have become a staple of modern architecture because of their sublime aesthetics. The transparent flow of natural light deep into the building interiors, and glass facades provides transparency reducing the need for artificial illumination, and creating bigger, brighter and more energising spaces.

- Maximizing Natural Light: A well-designed glass facade building adds an additional layer of visual appeal by strategically orienting and specifying high-performance glass. They also contribute significantly to energy efficiency and architects can optimise reliance on artificial lighting during the day.

- Connecting with the Outdoors: Depending on the vision, glass facades blend the interior and exterior seamlessly creating unobstructed views of the urban landscape. This adds to the well-being aspect of the structure and creates a more dynamic indoor environment.

- Aesthetic Versatility: From sleek, minimalist designs to bold, sculptural expressions, glass facades offer immense aesthetic versatility. Advancements in glass technology, including various tints, coatings, and structural capabilities, allow architects to realize their most ambitious visions.

The Elegance and Engineering of Curtain Wall Glazing

Currently, glass curtain walls are a splendid and sophisticated approach to facade design, for those who have a specific taste. They offer a lightweight, non-structural external covering that gives aesthetic flexibility with supreme performance.

- Seamless Integration: The smooth and seamless surfaces of glass lend a contemporary elegance to the urban architecture that often features curtain wall glazing systems and suspended glass assemblies.

- Performance and Efficiency: Curtain wall glazing systems of today incorporate advanced technologies for better efficiency, thermal insulation, and acoustic performance. High-performance glass, coupled with carefully engineered framing systems, ensures occupant comfort and reduces energy consumption.

- Design Freedom: Glass curtain walls allow for the creation of complex and dynamic architectural canopies and building forms. The ability to integrate various types of glass and infill panels provides architects with immense design freedom to shape the visual identity of a structure.

Beyond Vertical Walls: Innovative Glass Applications

The adaptable factor of glass contributes beyond the typical facades, adding on to the “breathing” capabilities of the structure in innovative ways.

- Modern Skylights: Modern skylights bring natural light into the deepest parts of a building, often transforming dimly lit spaces into vibrant surroundings that feel sensational. Often utilizing frameless glass roofs, these openings enhance natural ventilation that feels unusually vibrant.

- Architectural Canopies: Elegant glass canopies define the entrance of a structure, creating a welcoming atmosphere and smoothly transitioning into the rest of the spaces. Their lightweight and transparent nature not only provides shelter but also minimizes visual obstruction.

- Suspended Glass Assemblies: Beyond curtain walls, suspended glass assemblies can create dramatic interior and exterior features, such as glass walkways, partitions, and even secondary facade layers that allow for airflow and light diffusion.

Engineering Facades That Breathe

At Aparna Enterprises Ltd., our commitment to innovation and quality drives us to provide cutting-edge facade solutions that embody the principles of “breathing” architecture. Through our expertise in glass facades, including sophisticated glass curtain walls and elegant architectural canopies, we empower architects and developers to create buildings that are not only visually stunning but also environmentally responsible and enhance the well-being of their occupants. Our focus on precision engineering and high-performance materials ensures that our facade systems contribute to energy efficiency, natural light optimization, and a seamless integration with the urban environment.

The future of building facades design lies in creating structures that transcend the concept of static barriers. By embracing the possibilities of glass facades, innovative curtain wall glazing, and other dynamic glass applications, we can design buildings that truly breathe – maximizing natural light and ventilation, fostering a connection with the outdoors, and ultimately creating healthier, more sustainable, and more vibrant urban environments. Aparna Enterprises Ltd. is proud to be at the forefront of this evolution, engineering facades that not only define the skyline but also enhance the very experience of urban living.