READY MIX CONCRETE

Ready mix concrete(RMC) is a pre-mixed blend of cement, aggregates, water, and additives, crafted in specialized batching plants. Tailored to meet specific project requirements, RMC offers superior consistency and quality compared to on-site mixing, ensuring reliable and efficient construction.

Benefits of Ready Mix Concrete

Ready-mix concrete has changed the industry of construction due to its versatility, convenience, quality and quality. Being manufactured in a controlled environment, this versatile material ensures precise mixtures tailored to your specific project requirements , minimising on-site hazards and delivering superior strength and durability. Following are some of the benefits of using a ready-mix concrete:

- Quality Assurance: RMC is produced under strict quality control, ensuring a high-quality mix that meets all building requirements for stronger, longer-lasting structures.

- Consistency: RMC offers consistent quality and performance across batches, reducing variability in concrete strength and durability.

- Reduced Wastage: Precise batching and mixing reduce material wastage, saving costs.

- Time Efficiency: RMC is ready to use, saving time on construction sites and helping projects with tight deadlines finish faster while reducing labor costs.

- Cost-Effectiveness: Though initially more expensive than on-site mixing, RMC saves on labor, equipment, and rework, making it economical in the long run.

- Enhanced Safety: Controlled production in dedicated plants improves site safety by minimizing on-site mixing hazards.

- Customizability: With a variety of mix designs available, RMC can be tailored to specific project requirements, including strength, durability, and workability.

What We Offer

- High-Quality Concrete: Produced in advanced batching plants for superior consistency.

- Custom Solutions: Tailored concrete options for all project types.

- Reliable Delivery: Timely, round-the-clock delivery with a robust fleet.

- Expert Support: Planning, budgeting, and technical assistance.

What Makes Us Unique

High-Reliability for Large-Scale Projects- On-time delivery with digital trust

- Robust infrastructure with 70+ pumps and 300+ transit mixers to meet high and varying customer demands

- Produced through ISO-certified and QCI plants

Consistent, High-Quality Concrete

- Top-notch complaint resolution system

- IT-enabled and SAP-controlled batching plants

- Technology from leading OEMs like Schwing Stetter and Putzmeister

Innovation and Sustainability

- Independent R&D division

- Sustainable Practices Using Green Concrete

- Extensive portfolio of concrete solutions for diverse project needs

Extensive Value-Added Concrete Portfolio

At Aparna RMC, we offer a diverse range of specialty concrete solutions tailored to meet the unique demands of various construction projects. Our innovative and high-performance products ensure that every project, from residential builds to large-scale industrial structures, receives the best possible concrete mix for its specific needs like optimal performance, durability, and aesthetic appeal.1.SkyCrete: High-grade Concrete

2.ConviCrete: Slab Concrete for IHB

3.SwiftFlowMix: Self-Compacting Concrete (SCC)

4.FlexiCrete: Smart Dynamic Concrete

5.AstraGlowCrete: Green Concrete

6.AsthetiCrete: Colored Concrete

7.CraftCrete: Stamped Concrete

8.EchelonCrete: Lightweight Concrete

9.Elasticrete: PP Fiber Reinforced Concrete

10.Ducticrete: Steel Fiber Reinforced Concrete

11.Tempcrete: Temperature Control Concrete

12.GlassCrete: Glass Fiber Reinforced Concrete

Key Projects

1.Rajiv Gandhi International Airport, Hyderabad2.Namma Metro, Bangalore

3.Secunderabad Railway Station New Design, Hyderabad

4.Sobha Universal, Mumbai

5.The Park Hyatt, Hyderabad

Comparative Chart

Aparna RMC v/s Site Mix Concrete

| PARAMETER | Aparna RMC | SITE MIX CONCRETE |

|---|---|---|

| Storage space for raw materials needed | No | Yes |

| Wastage of raw material at the site | Nil | More |

| Weighing the material | Computerized | Manually |

| Adjustment for admixture | Computerized | Approx. |

| Addition of water | Computerized | Manually |

| Addition of admixture | Computerized | Manually |

| Mixing | Computerized | Manually |

| Mixing time | Computerized | By mixer operator |

| Output in 8 hrs/mixer (by considering the operational capacity of 70%) | 320 Cu. M. | 16 Cu. M. |

| Quality control | Excellent | Fair |

| Yield | Consistent | Variable |

| Testing of fresh concrete | Each batch | Only once/2.5 batches |

| Delivery of concrete | By transit mixer | Manually |

| Placing of concrete at heights | Concrete pump | Manually / hoist 1.5 Cu. M./hr |

| Slab finishing | Excellent | Fair |

| Construction speed | Fast | Very slow |

| Supervised by | Aparna RMC | Client |

| Testing cost | Aparna RMC | Client |

Note: Delivery time is subject to traffic restrictions, proximity to the civil site, and distance from the plant, which may affect to-and-fro transportation.

ABOUT APARNA RMC

Aparna RMC leads the industry with expansive mixing technology, the largest single-pouring capacity, and the broadest production footprint across Telangana, Andhra Pradesh, Maharashtra, and Karnataka. Investing in cutting-edge technologies and research, we offer a comprehensive portfolio of concrete solutions for projects ranging from residential to mega-industrial. We produce over 1.8 million cubic meters annually and utilize fully automated batching plants and seamless digitalized operations. With 29 plants, 70 transit mixers, and 5 boom pumps, we cater to high-rise structures and dynamic construction needs. Our made-to-order concrete guarantees precise grades and quantities, delivered by our dedicated fleet, 24/7.

Visit WebsiteFEATURES & BENEFITS

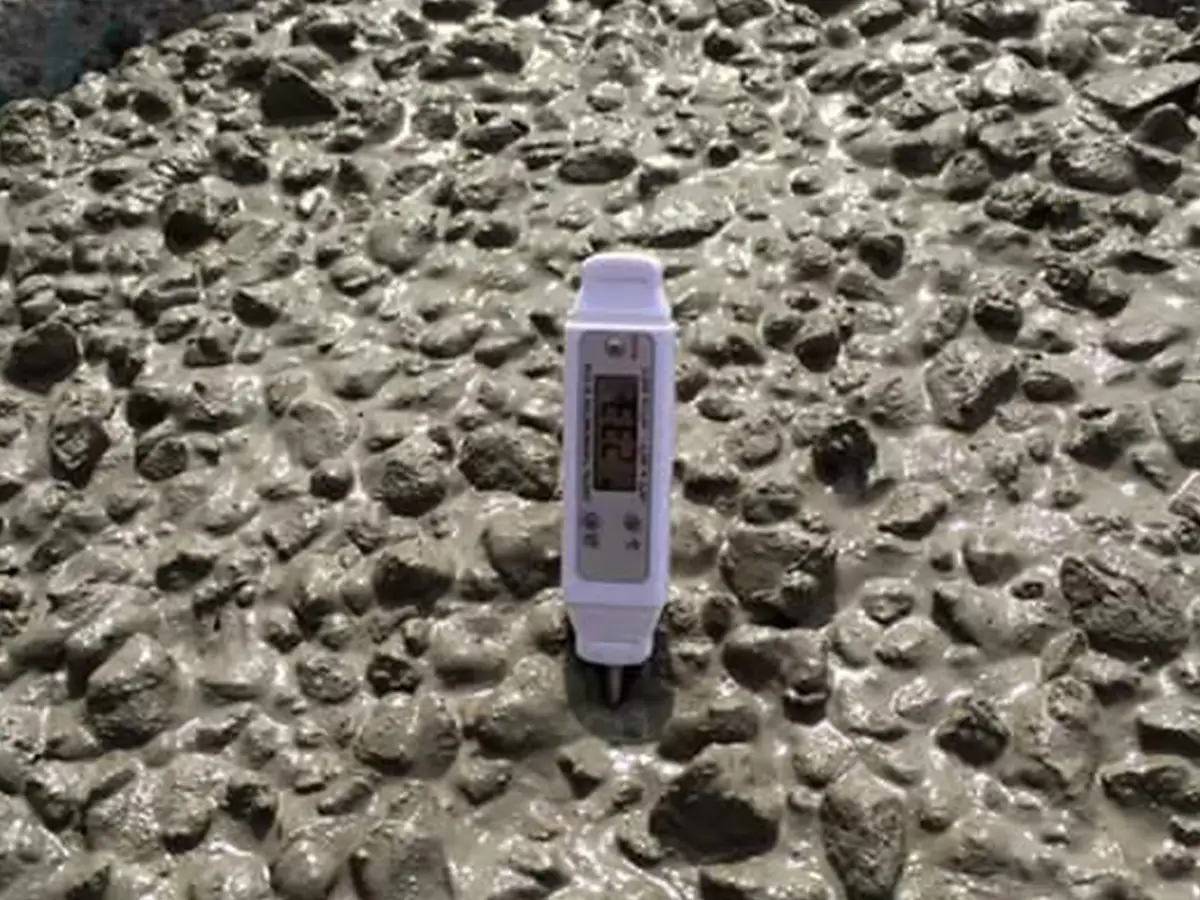

PRODUCT IMAGES

Say Hello

For further information or queries about our products and services, feel free to contact us!!

Unveil the magic of building together!!

HYDERABAD CORPORATE OFFICE

Aparna Enterprises Ltd.

8-2-293/82/A, Plot No-1214, Road No-60,

Jubilee Hills, Hyderabad-500 033.

CIN no.: U51109TG1994PLC018950